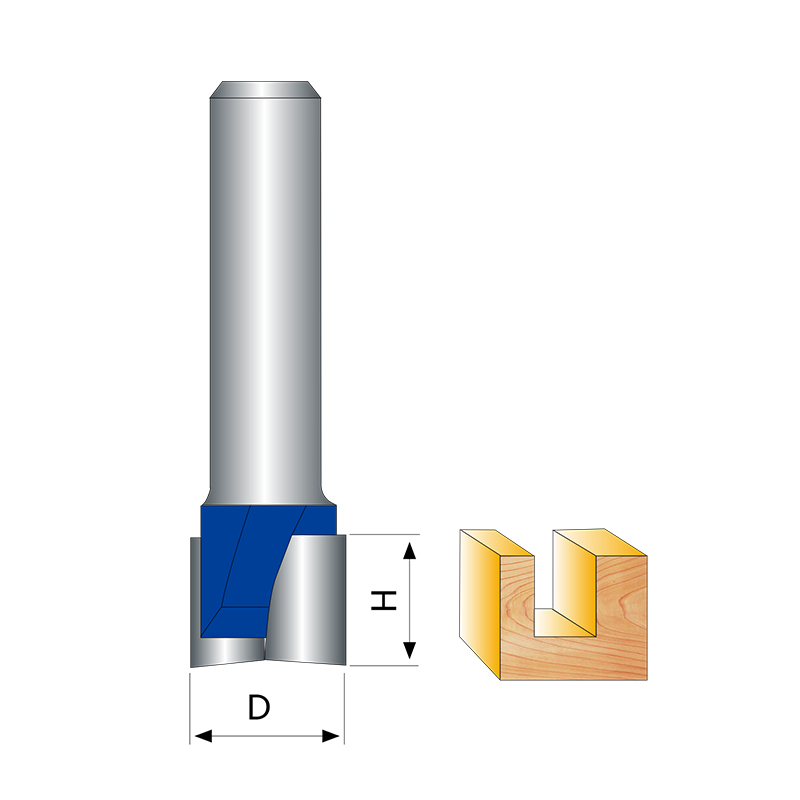

In the realm of precision tools for woodworking and material fabrication, Bottom Cleaning Bits are indispensable assets, known for their ability to achieve clean finishes and thorough residue removal. These specialized tools excel in clearing remnants from the base of cuts and ensuring a smooth cutting surface. Crafted with flat blades, they are particularly effective in cleaning grooves and planar surfaces with precision and efficiency.

In conclusion, Bottom Cleaning Bits represent a pinnacle of precision and functionality in the realm of woodworking tools. Their ability to meticulously clean residues, create smooth cutting surfaces, and adapt to various applications makes them indispensable for craftsmen and fabricators alike. Whether clearing mortises, cleaning grooves, or preparing surfaces for assembly, these bits ensure that every project meets exacting standards of quality and precision. Discover the difference that Bottom Cleaning Bits can make in your workshop, where attention to detail and good craftsmanship converge seamlessly.