Product Advantages

1. Tailored for T-slot Cutting

- Designed specifically to excel in T-shaped groove cutting, this cutter ensures exacting precision in every operation.

- Its optimized blade geometry allows for swift and efficient cutting, reducing production time while maintaining good accuracy.

- The cutter's high-speed capabilities streamline workflow, enhancing productivity without compromising on quality.

2. High Precision

- Engineered with meticulous attention to detail, each "T" Type Slotting Cutter guarantees consistent and clean cuts.

- Precision-ground blades minimize splintering and ensure smooth edges, crucial for achieving professional-grade finishes.

- This precision extends to various wood types and thicknesses, accommodating diverse woodworking requirements.

Product Features

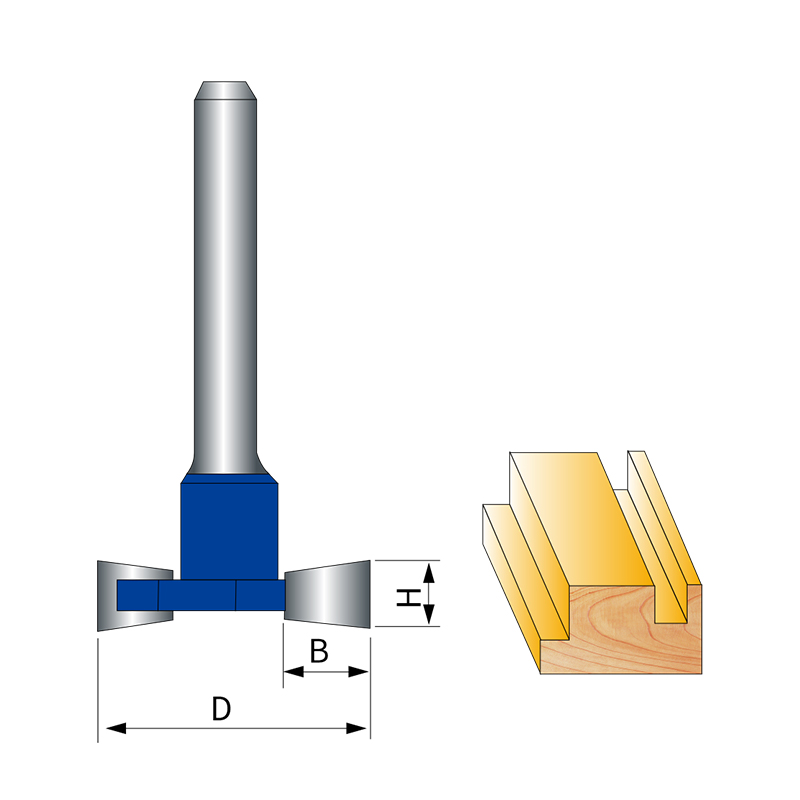

1. T-shaped Blade Design

- The unique T-shaped blade profile is crafted to deliver sharp and accurate cuts, essential for intricate woodworking projects.

- Integrated chip breakers enhance chip evacuation, maintaining cutting efficiency even in dense hardwoods.

- Anti-kickback design promotes safer operation by reducing the risk of tool recoil during use.

2. High-Quality Alloy Materials

- Manufactured from premium alloy materials, each cutter exhibits exceptional durability and wear resistance.

- Heat-treated blades maintain sharpness over extended periods, ensuring prolonged tool life and consistent performance.

- Corrosion-resistant coatings protect against environmental factors, ideal for both indoor and outdoor woodworking applications.

3. Variety of Sizes

- Available in a range of sizes, from small diameters for intricate detailing to larger profiles for structural components.

- Versatile sizing options cater to different project requirements, offering flexibility in groove dimensions and depths.

- Each size variation maintains the same high standards of precision and durability, meeting the demands of diverse woodworking tasks.

Product Applications

1. Construction of T-shaped Grooves

- Primary application involves the precise fabrication of T-shaped slots, crucial for interlocking and securing structural elements in furniture and cabinetry.

- Facilitates seamless joint fitting, ensuring robust connections and enhanced load-bearing capacity.

- Enables intricate woodworking designs by facilitating precise groove dimensions and alignments.

2. Architectural Embellishments

- Utilized architectural woodworking to create decorative T-shaped details in panels, moldings, and custom millwork.

- Enhances the aesthetic appeal of interior spaces through precise groove patterns and seamless integration with existing architectural elements.

- Supports creative freedom in designing bespoke woodwork features that reflect unique architectural styles and preferences.

3. Custom Furniture Manufacturing

- Essential tool for furniture makers in crafting bespoke pieces requiring precise joint fittings and structural integrity.

- Facilitates the assembly of complex furniture designs, ensuring durability and longevity through secure joint connections.

- Enhances craftsmanship by enabling intricate detailing and precise machining, contributing to the overall quality and value of custom-made furniture.